To each and every one of you who left a comment about this new fountain from Branch, my sincere thanks. It was a sculpture that was months in the making. So much conversation. So much thought. So many members of the Branch group stepping up. All of us fell for this fountain. We are pleased that you like it too. This morning my colleague, friend, and director of landscape services for English Gardens, John Collins, brought an operator in on a Saturday, who drove his Volvo 6000 pound capacity front end loader several miles down Orchard Lake Road to Detroit Garden Works. Our front end loader could not unload and place this fountain. We needed help, and our good friends at English Gardens responded.

To each and every one of you who left a comment about this new fountain from Branch, my sincere thanks. It was a sculpture that was months in the making. So much conversation. So much thought. So many members of the Branch group stepping up. All of us fell for this fountain. We are pleased that you like it too. This morning my colleague, friend, and director of landscape services for English Gardens, John Collins, brought an operator in on a Saturday, who drove his Volvo 6000 pound capacity front end loader several miles down Orchard Lake Road to Detroit Garden Works. Our front end loader could not unload and place this fountain. We needed help, and our good friends at English Gardens responded.

Branch spends some of the winter building containers, pergolas and fountains outside of our usual product line. The best part of a fierce winter at Branch is the opportunity to go beyond what we have already done. Imagination is like an ocean, water charged with energy washing up on the shores of what has been before. Branch manufactures a stock group of garden boxes, fountains and pergolas. But in the winter, we go off course, we dream, and we make what we have never made before. This winter work gets all of our blood moving, in spite of the cold. But my lame attempt at a poetic description of the creation of this fountain lags far behind the story and reality of moving an object that weighs close to 2 tons.

Branch spends some of the winter building containers, pergolas and fountains outside of our usual product line. The best part of a fierce winter at Branch is the opportunity to go beyond what we have already done. Imagination is like an ocean, water charged with energy washing up on the shores of what has been before. Branch manufactures a stock group of garden boxes, fountains and pergolas. But in the winter, we go off course, we dream, and we make what we have never made before. This winter work gets all of our blood moving, in spite of the cold. But my lame attempt at a poetic description of the creation of this fountain lags far behind the story and reality of moving an object that weighs close to 2 tons.  John, and his Volvo, handled it with ease. I truly value the relationships I have with other companies in my field. English Gardens has many garden centers in our area. They speak to a broad spectrum of clients via their retail locations. They also offer and deliver thoughtful landscape design and installation. They are friends and treasured colleagues. I so appreciate that they would lend me a hand. On a Saturday, of course. All of us are busy working during the week this time of year. And especially busy, given how shy spring has been to make an appearance.

John, and his Volvo, handled it with ease. I truly value the relationships I have with other companies in my field. English Gardens has many garden centers in our area. They speak to a broad spectrum of clients via their retail locations. They also offer and deliver thoughtful landscape design and installation. They are friends and treasured colleagues. I so appreciate that they would lend me a hand. On a Saturday, of course. All of us are busy working during the week this time of year. And especially busy, given how shy spring has been to make an appearance.

Once the fountain was in the general vicinity of its home, we set it down with the loader forks. We picked it up again with straps slung over the forks, to place it true and square to the wall.

Once the fountain was in the general vicinity of its home, we set it down with the loader forks. We picked it up again with straps slung over the forks, to place it true and square to the wall.

Once in place, Buck and Sal saw to attaching the jet. The jet pipe was threaded by hand, and screws into the base plate welded to the fountain floor. The jet needed a secure installation, as it weighs close to fifty pounds.

Once in place, Buck and Sal saw to attaching the jet. The jet pipe was threaded by hand, and screws into the base plate welded to the fountain floor. The jet needed a secure installation, as it weighs close to fifty pounds.

Any fountain demands a perfectly level placement. Water levels itself with the horizon. A fountain out of level -not good. The water will talk about any mistake. We spent a good bit of time with a pallet jack and a level. Any fountain asks for as close to a perfectly level placement as possible. Leveling is the most time consuming part of a permanent installation. When filled over the top, the water should flow over every inch of the rim equally, and at the same time.

Any fountain demands a perfectly level placement. Water levels itself with the horizon. A fountain out of level -not good. The water will talk about any mistake. We spent a good bit of time with a pallet jack and a level. Any fountain asks for as close to a perfectly level placement as possible. Leveling is the most time consuming part of a permanent installation. When filled over the top, the water should flow over every inch of the rim equally, and at the same time.

The Branch fountain has a rectangular housing for the pump. It has a jet in the same style, shape, and proportion as the fountain itself.

The Branch fountain has a rectangular housing for the pump. It has a jet in the same style, shape, and proportion as the fountain itself.

The rectangular pump cover encloses all of the workings of the pump. No one needs to see this. The fountain could be hard wired with a remote location for the pump, if an installation warranted that. But for now, it can be fired up by plugging it in.

The rectangular pump cover encloses all of the workings of the pump. No one needs to see this. The fountain could be hard wired with a remote location for the pump, if an installation warranted that. But for now, it can be fired up by plugging it in.

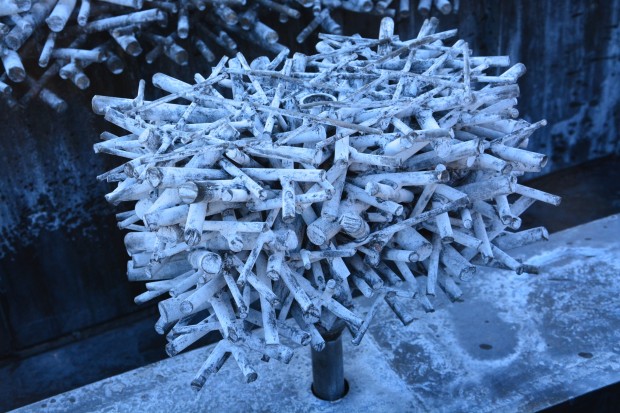

This steel nest jet breaks the water falling from a very powerful pump. The music that a fountain produces is important. I could not be more pleased with the sound. It is musical, not at all metallic.

This steel nest jet breaks the water falling from a very powerful pump. The music that a fountain produces is important. I could not be more pleased with the sound. It is musical, not at all metallic.

The fountain filling and the pump running – a moment I will not soon forget. There is such pleasure in bringing the construction to a close, and attending opening day. We have 3 other fountains just about finished at Branch. More on that when they are actually here and running. Buck says we will have them within two weeks. It has only been within the last 10 years that I have seriously considered water as a feature in the landscape. Now I would not want to do without it. No matter the size or scale, water in the garden is a pleasure. Bring on the ponds, birdbaths and fountains.

The fountain filling and the pump running – a moment I will not soon forget. There is such pleasure in bringing the construction to a close, and attending opening day. We have 3 other fountains just about finished at Branch. More on that when they are actually here and running. Buck says we will have them within two weeks. It has only been within the last 10 years that I have seriously considered water as a feature in the landscape. Now I would not want to do without it. No matter the size or scale, water in the garden is a pleasure. Bring on the ponds, birdbaths and fountains.

The Branch fountain is now on display at Detroit Garden Works. Thanks again for all the comments and calls-we all appreciate every one of them. Should you live nearby, we invite you to stop in and see for yourself.

The Branch fountain is now on display at Detroit Garden Works. Thanks again for all the comments and calls-we all appreciate every one of them. Should you live nearby, we invite you to stop in and see for yourself.